A few weeks ago, a complete, high-performance poultry farming system successfully departed from our factory, destined for a major farm in Pakistan. This shipment, meticulously prepared and loaded into a 40-foot container, underscores our commitment to supporting the agricultural sector in Pakistan with robust and efficient machinery.

This wasn't just a shipment of individual items; it was the delivery of a fully integrated environment control and feeding solution for five modern poultry houses. Understanding the specific challenges of the Pakistani climate, particularly the intense heat, our team worked closely with the client to configure a system that promises enhanced productivity and bird welfare.

The core of this shipment included five key components, each selected for its reliability and performance:

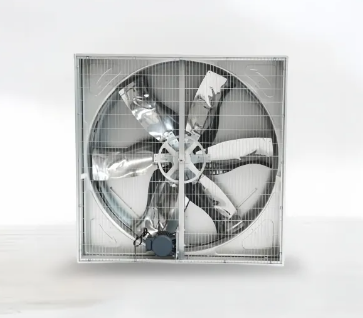

1. High-Efficiency Exhaust Fans:At the heart of the ventilation system are our heavy-duty exhaust fans. Engineered for maximum airflow with minimal energy consumption, these fans are crucial for removing hot air, moisture, and harmful gases like ammonia from the poultry houses. This ensures a constant supply of fresh air, which is vital for maintaining optimal health and growth rates in flocks, especially during Pakistan's scorching summers.

2. Durable Feed Silo: To ensure a reliable and hygienic feed supply, we supplied a large-capacity feed silo. Constructed from galvanized steel with a corrosion-resistant coating, this silo is built to withstand the elements and protect valuable feed from contamination and moisture. Its precise delivery system works in perfect harmony with the feeding mechanism, guaranteeing that birds have consistent access to nutrition.

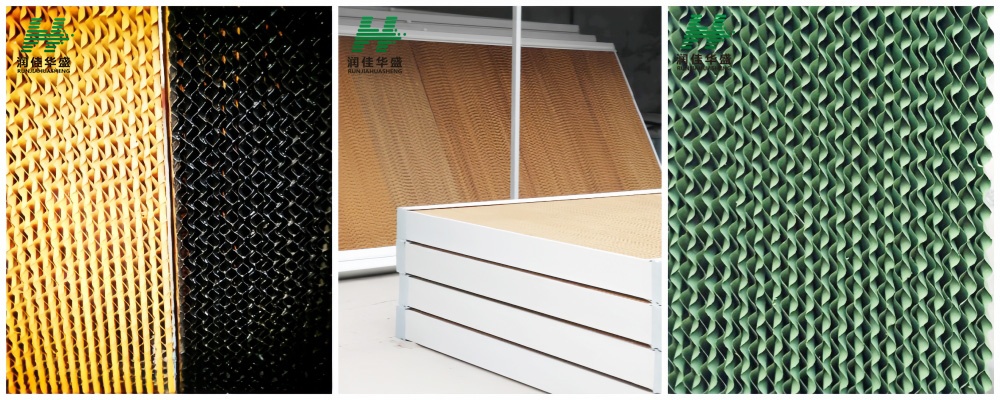

3. Advanced Cooling Pads: Recognizing the critical need for temperature management, the system includes our state-of-the-art cellulose cooling pads. These pads form the cornerstone of an evaporative cooling system. As hot outside air is drawn through the moistened pads, it is cooled significantly before entering the house. This proven method provides an economical and highly effective way to lower the internal temperature, creating a comfortable environment that reduces heat stress on the birds.

4. Automated Feeding System: Efficiency in feeding is key to modern poultry farming. Our automated feeding system was included to eliminate labor-intensive manual feeding. This system ensures a uniform and timely distribution of feed throughout all five houses, promoting consistent growth across the entire flock and optimizing feed conversion ratios.

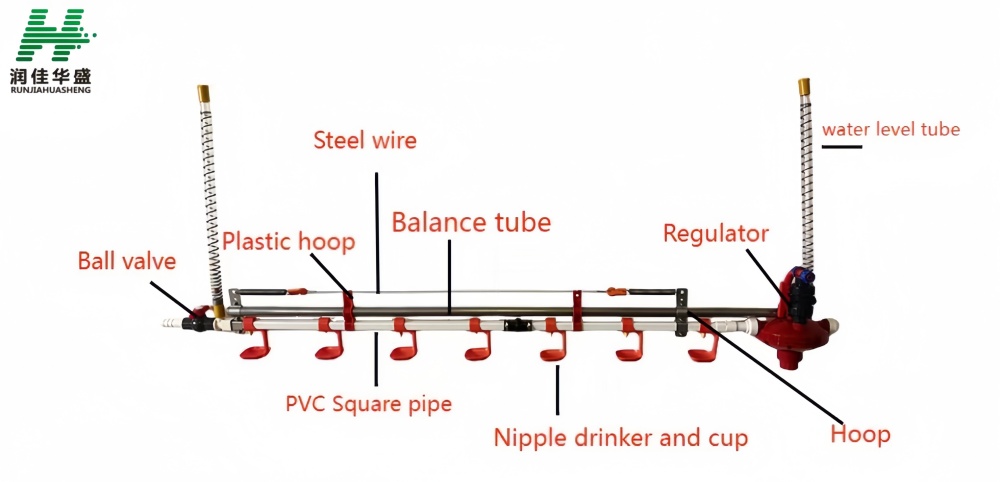

5. Nipple Drinking Systems:Providing a constant supply of clean, fresh water is non-negotiable. The included nipple drinking systems are designed to minimize water wastage and prevent spillage, which helps in keeping the litter dry and preventing disease. Made from high-quality, non-toxic materials, these drinkers encourage natural drinking behavior and support excellent bird health.

At Shandong Huasheng Husbandry Machinery, we believe in building partnerships, not just completing transactions. Our engineering team provided comprehensive support from the initial consultation through to the final loading schedule, ensuring the client was confident in the equipment and its setup. This project to Pakistan is a testament to our capability to deliver turnkey solutions that meet the specific demands of the international market.

We are proud to contribute to the advancement of poultry farming in Pakistan and look forward to receiving feedback on the performance of our systems. For poultry farmers seeking to enhance their operational efficiency and animal welfare standards, Shandong Huasheng Husbandry Machinery stands ready as your trusted partner in growth.